Components of BOSCH diesel systems

Components of BOSCH diesel systems

Bosch's direct injection systems have made diesel engines not only sportier, but also more economical. As a leading manufacturer of the diesel injection systems, Bosch supplies diesel engine components to manufacturers worldwide.

Distinctive advantages of Bosch

- Strict quality control during production.

- Quality assurance. BOSCH gives a guarantee for every part produced.

- A wide range of auto parts for the aftermarket and repair shops.

- Reasonable prices. Despite the popularity of the brand, the manufacturer tries to maintain reasonable and competitive prices, which makes Bosch components affordable for everyone.

In-line diesel fuel injection pump

Better cylinder performance with lower fuel consumption and reduced exhaust emissions are guaranteed: The Bosch In-line diesel fuel injection pump is used in commercial vehicles, construction and agricultural machinery and stationary engines.

Common Rail fuel injection system pump

Always ensure a constant supply of fuel with the required accurate injection level, regardless of the situation on the road: The Bosch Common Rail fuel injection pump compresses fuel up to 2700 bar and delivers the required amount with high precision.

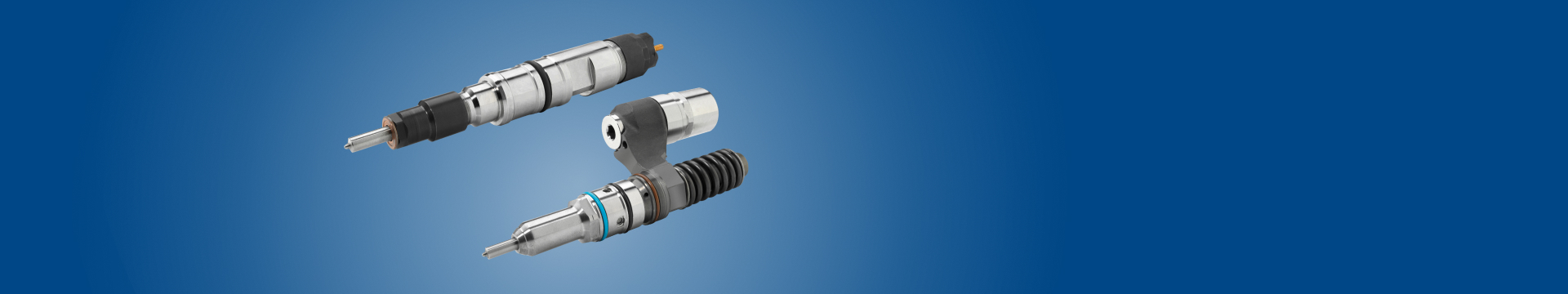

Common Rail fuel injector

Quiet, high-efficiency combustion in any traffic situation is guaranteed: The injector of Bosch Common Rail fuel injection system injects fuel with high precision directly into the combustion chamber.

Unit injector system

Maximum power and fuel economy guaranteed: The Bosch unit injector system is an injector assembly with holders, an integrated high-pressure pump, providing pressure of up to 2200 bar in the injector spray nozzle for an optimal air/fuel mixture.

Plunger and barrel assembly

Be assured of high performance for hundreds of thousands of miles: Bosch plunger and barrel assemblies consist of a pump piston and a cylinder made using particularly high-quality production methods and material.

Shut-off valve

For guaranteed peace of mind: Bosch shut-off valves are made with very high precision, using premium materials, both of which are essential requirements for one of the most stressed components of the injection system.