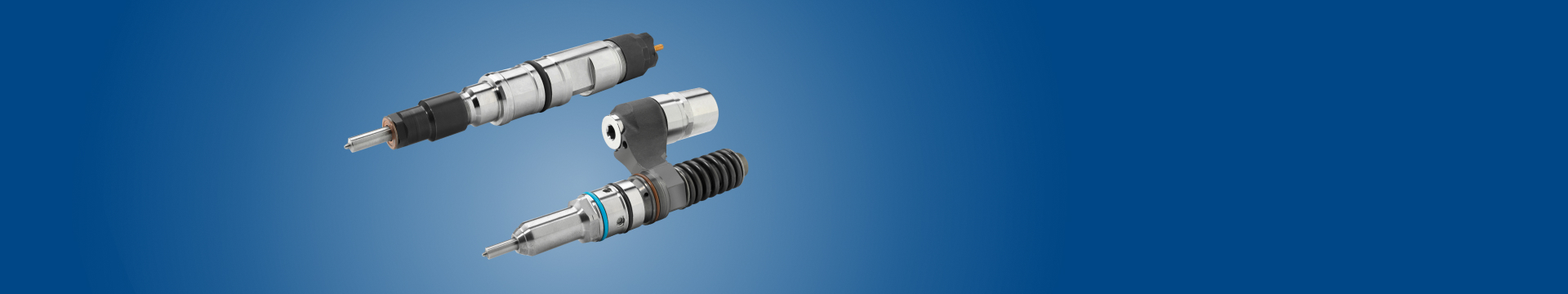

Components of AZPI diesel systems

Altai Precision Components Plant is a Russian leader in the production of fuel injection equipment for diesel engines of all types that meet the cutting-edge international environmental requirements. AZPI was founded in 1991 on the basis of the fuel equipment workshop of the Altai Motor Plant. One of the main activities of the Altai Precision Components Plant is electrically controlled fuel injection equipment. Complete Common Rail fuel supply systems for engines of environmental classes EURO-4 and EURO-5, injectors and spare parts for them. As part of the ongoing import substitution program, more than 150 models of spray nozzles have been developed and produced, and are successfully used in the aftermarket of the imported equipment. AZPI sells injectors of its own design and spare parts for them, which can be installed on engines of both Russian and foreign production. The production division of warranty and service is engaged in intensive development of the network of authorized centers for maintenance and repair of AZPI-Service fuel injection equipment. More than 300 modifications of spray nozzles, more than 80 modifications of injectors have been developed and launched into commercial production. Continuous renewal and modernization of fixed assets, development and implementation of advanced technologies. AZPI is one of the ten world leaders in the development and production of fuel injection equipment.

Distinctive advantages of AZPI

- Supplier of complete Common Rail fuel systems for KAMAZ Conveyor No. 1 in Russia.

- One of the five world leaders in the production of fuel injection equipment.

- The high level of production allows us to compete with the major foreign manufacturers of fuel injection equipment.

- More than 60 years of manufacturing experience.

- More than 550 modifications of spray nozzles and valves with a stem, as well as more than 80 modifications of injectors, have been developed and launched into commercial production.